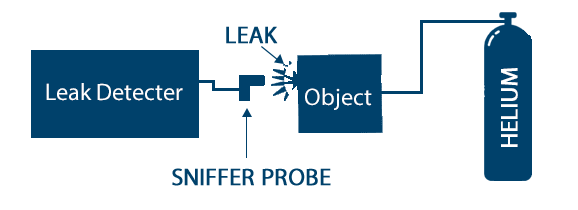

SNIFFER PROBE

Due to the innate properties of helium it readily migrates throughout the system and in its attempt to escape penetrates any imperfections.

Due to the innate properties of helium it readily migrates throughout the system and in its attempt to escape penetrates any imperfections.

When using the sniffer probe technique for a helium leak test inspection, helium is first purged throughout the inside of system. Due to the innate properties of helium it readily migrates throughout the system and in its attempt to escape penetrates any imperfections, including: defective welds (caused by cracks, pin holes, incomplete welds, porosity, etc.), flawed or missing gaskets, leaks due to loose clamps, or any other defect. The system’s exterior is then scanned by using a probe attached to the leak tester. Any leaks will result in an increased level of helium nearest the source and be readily detected. Leak sources can then be pinpointed, providing the opportunity for immediate repair and retest.

Unlike the spray probe technique, this process is very flexible and can be adapted to meet the needs of virtually any system in which helium can be injected. There is no practical size limitation. The sniffer probe technique is not as sensitive as the spray probe process, however, due to the amount of helium present in the air (approximately 5 ppm). The maximum sensitivity achievable under this procedure is approximately 1×10-6 std cc/sec. Nevertheless, this process is vastly superior to other traditional leak testing methods, such as: bubble testing, acoustic emission, liquid penetrant or vacuum box testing.